Rafination of Metals

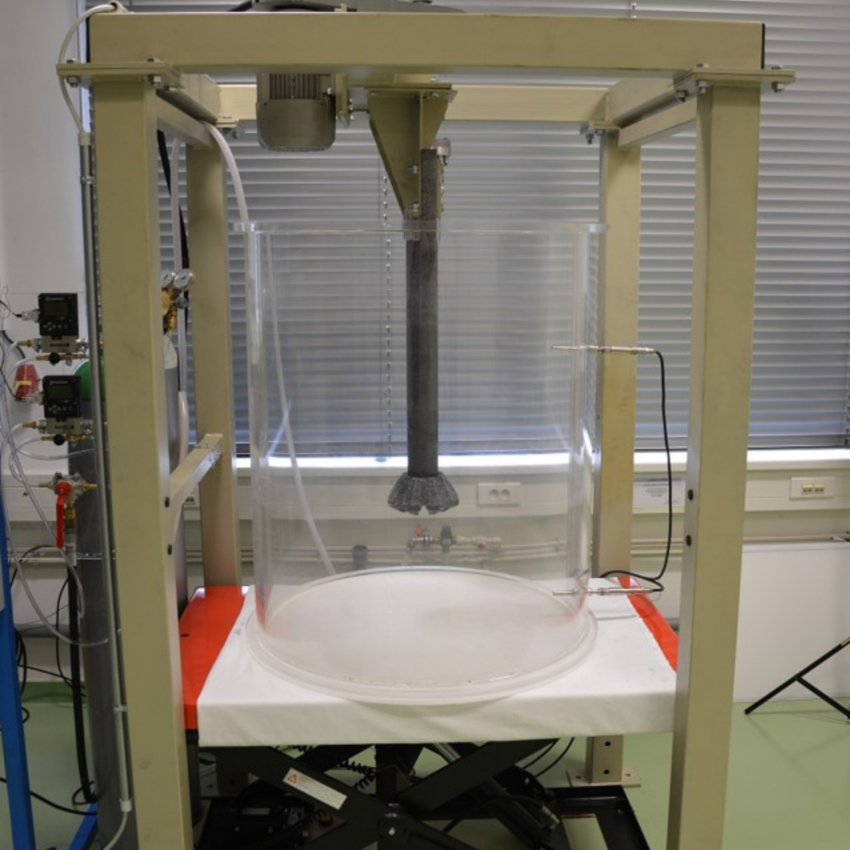

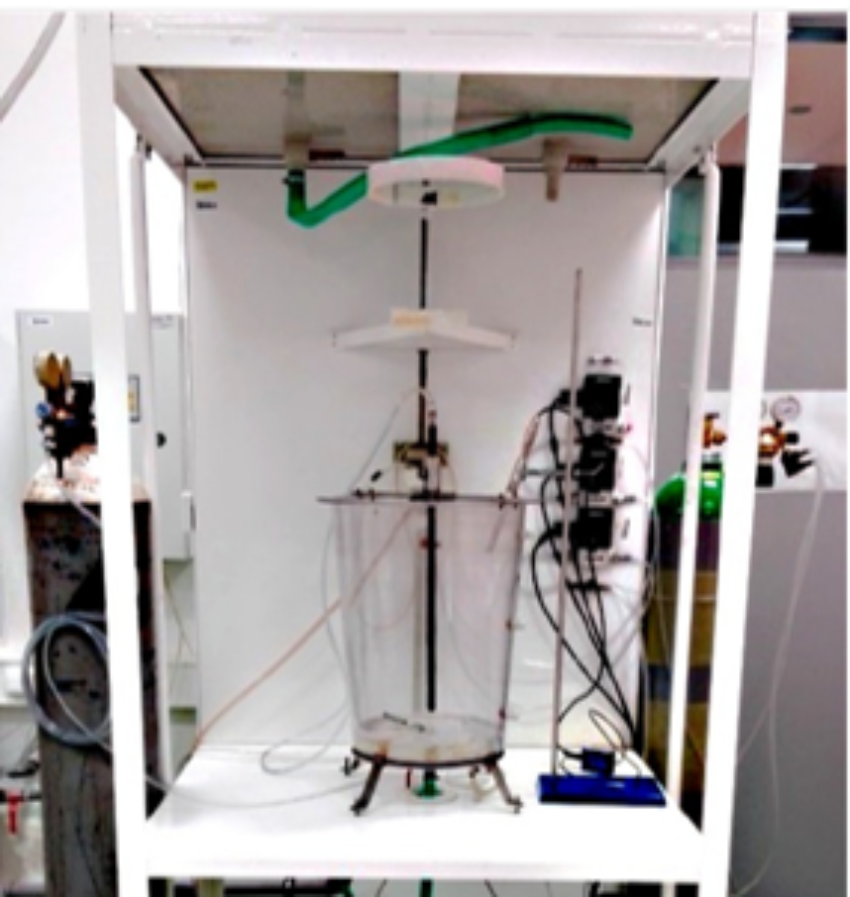

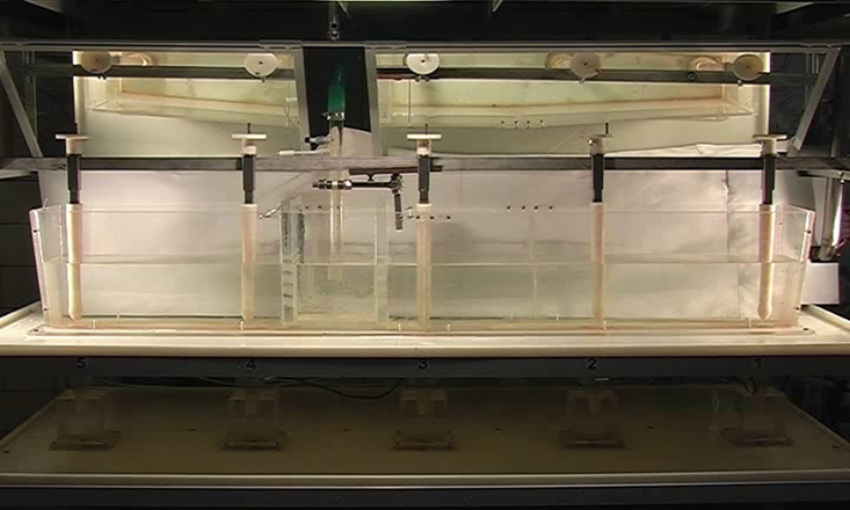

- Physical modelling of melt degassing in the refining ladle

- Equipment for carrying out experiments using the physical modeling method, which can be used to optimize relevant parameters such as impeller speed, blowing argon (or nitrogen) flow, impeller shape, impeller height above the bottom of the ladle, etc.

- The findings are further verified using the numerical modeling method in the CFD environment of the ANSYS Fluent program.The results achieved can be transformed into actual equipment conditions.